In a world grappling with climate change and food insecurity, scientists and innovators are turning to unconventional solutions to feed a growing population. One of the most groundbreaking developments in recent years is the concept of air protein—a flour-like substance derived from carbon dioxide. This technology promises to transform the way we think about food production, offering a sustainable alternative to traditional agriculture.

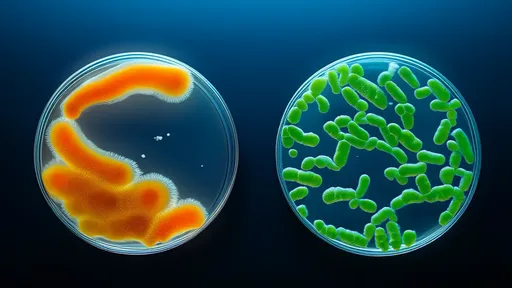

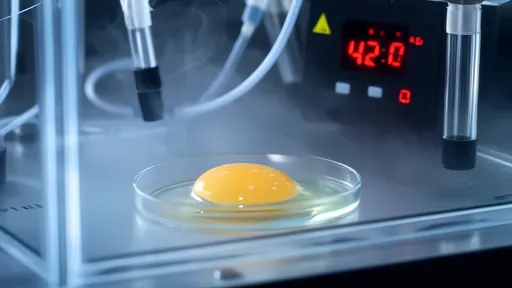

The process of creating air protein involves harnessing microorganisms that convert carbon dioxide into edible protein. These microbes, often referred to as hydrogenotrophs, consume CO2 and hydrogen, producing a nutrient-rich biomass. When dried and processed, this biomass can be turned into a fine powder resembling flour. The implications of this technology are profound, particularly in regions where arable land is scarce or where climate conditions make conventional farming challenging.

Why Air Protein Matters

Traditional agriculture is one of the largest contributors to greenhouse gas emissions, deforestation, and water depletion. Livestock farming alone accounts for nearly 15% of global emissions. Air protein, on the other hand, requires a fraction of the land and water needed for crops or livestock. It can be produced in controlled environments, such as bioreactors, eliminating the need for pesticides, fertilizers, or vast tracts of farmland. This makes it an attractive option for reducing the environmental footprint of our food systems.

Beyond sustainability, air protein offers nutritional benefits. The microbial biomass is rich in essential amino acids, making it a complete protein source. It can be fortified with vitamins and minerals, addressing malnutrition in vulnerable populations. Unlike plant-based proteins, which often require extensive processing to improve taste and texture, air protein can be engineered to mimic the flavors and mouthfeel of conventional foods, from bread to pasta.

The Science Behind the Innovation

The technology behind air protein builds on decades of research in industrial microbiology and gas fermentation. Companies like Solar Foods and Air Protein have pioneered methods to scale this process efficiently. Their bioreactors function similarly to breweries, but instead of fermenting sugars, they ferment gases. The result is a protein-rich substance that can be harvested, purified, and dried into a versatile flour.

One of the key challenges has been optimizing the efficiency of the microbial strains used in the process. Through genetic engineering and selective breeding, scientists have developed strains that produce higher yields and require less energy input. Advances in renewable energy have also played a crucial role, as the process relies on hydrogen produced via electrolysis—ideally powered by solar or wind energy to maintain its low-carbon footprint.

Potential Applications and Market Readiness

The first commercial products featuring air protein are expected to hit the market within the next few years. Initial applications will likely focus on protein supplements and meat alternatives, but the real game-changer lies in its use as a flour substitute. Imagine a world where bread, pasta, and baked goods are made from carbon dioxide-derived flour, drastically reducing the environmental cost of staple foods.

Developing nations, where food scarcity is a pressing issue, could benefit immensely from decentralized air protein production. Small-scale bioreactors could be deployed in remote areas, providing a reliable source of nutrition without the logistical challenges of transporting perishable goods. In urban centers, air protein could complement vertical farming initiatives, creating fully self-sustaining food ecosystems.

Challenges and Public Perception

Despite its promise, air protein faces hurdles before it can achieve widespread adoption. Regulatory approval is one obstacle, as food safety agencies must evaluate its long-term health impacts. Consumer acceptance is another critical factor. The idea of eating flour made from microbes and CO2 may seem unappetizing to some, requiring effective marketing and education to shift perceptions.

Cost is also a barrier. Currently, producing air protein is more expensive than conventional flour, though economies of scale and technological improvements are expected to drive prices down. As with any emerging technology, early adopters—particularly in the eco-conscious and fitness communities—will play a vital role in mainstreaming air protein.

A Glimpse Into the Future

If successfully scaled, air protein could redefine global food systems. It offers a way to decouple food production from environmental degradation, providing a lifeline in the fight against climate change. The vision of a carbon-negative food source—one that actively removes CO2 from the atmosphere while nourishing populations—is no longer science fiction.

The journey from lab to table will require collaboration between scientists, policymakers, and consumers. But with the stakes higher than ever, air protein represents more than just an innovation—it’s a potential cornerstone of a sustainable future.

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025